In the pharmaceutical industry, precision and quality assurance are paramount. Ensuring that every cartridge, vial, or syringe meets stringent quality standards is not only essential for regulatory compliance but also for patient safety. Our Cartridge Inspection Machine is designed to meet the exacting demands of the pharmaceutical sector, helping you maintain the highest levels of quality and reliability in your Production processes.

Our Mission:

At Cartridge Inspection Machine for Pharma Industries, our mission is crystal clear: to empower pharmaceutical manufacturers with cutting-edge inspection solutions that consistently deliver uncompromising quality. We understand the vital role these small yet critical components play in drug delivery and patient well-being, and we are dedicated to helping our clients achieve excellence in their manufacturing processes.

Our Solutions:

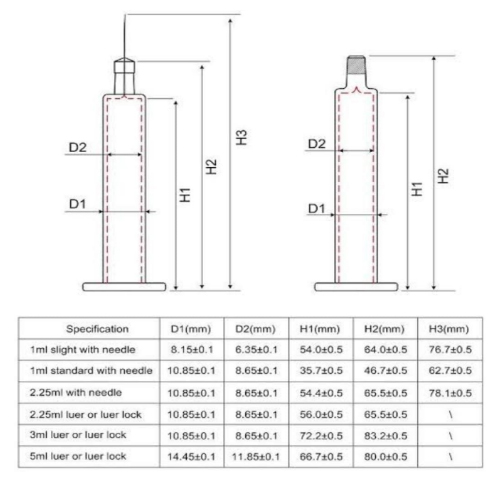

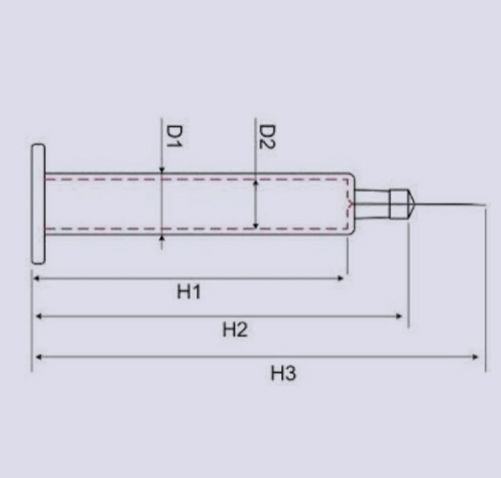

Advanced Inspection Technology: Our Cartridge Inspection Machine employs state-of-the-art technology to meticulously examine cartridges, vials, and syringes, ensuring they meet precise dimensional and quality specifications. With our systems in place, you can be confident in the quality and consistency of your pharmaceutical products.

Customized Solutions: We recognize that the pharmaceutical industry encompasses a wide range of products, from vaccines to injectable drugs. Our inspection solutions can be tailored to suit your specific needs, ensuring that each product type is inspected with precision and accuracy.

Real-time Data Analysis: Our systems provide real-time data analysis, allowing you to monitor the performance of your production processes and make immediate adjustments when necessary. This helps maintain the highest level of quality throughout your manufacturing operations.

Regulatory Compliance: Compliance with regulatory requirements is non-negotiable in the pharmaceutical industry. Our Cartridge Inspection Machine ensures that your products adhere to industry standards and regulatory specifications, helping you avoid costly recalls and regulatory issues.

Why Choose Us?

Industry Expertise: With years of experience in the pharmaceutical sector, we possess the expertise needed to address the unique challenges of drug manufacturing.

Cutting-Edge Technology: We stay at the forefront of technology trends, continuously updating our systems to incorporate the latest advancements in precision measurement.

Cost Efficiency: Our systems are designed to enhance efficiency and reduce waste, ultimately leading to cost savings for your operations.

Customer Support: We offer comprehensive customer support to ensure your inspection systems consistently perform at their best, minimizing downtime and maximizing productivity.

Contact Us:

Ready to elevate the quality of your pharmaceutical manufacturing? Contact us today to discuss your specific requirements and discover how our Cartridge Inspection Machine can enhance your operations. Our team of experts is eager to assist you in finding the ideal solution for your pharmaceutical inspection needs. Count on us for precision, reliability, and innovation in pharmaceutical manufacturing. Your patients deserve nothing less than the best, and we're here to help you deliver it.

Our Mission:

At Cartridge Inspection Machine for Pharma Industries, our mission is crystal clear: to empower pharmaceutical manufacturers with cutting-edge inspection solutions that consistently deliver uncompromising quality. We understand the vital role these small yet critical components play in drug delivery and patient well-being, and we are dedicated to helping our clients achieve excellence in their manufacturing processes.

Our Solutions:

Advanced Inspection Technology: Our Cartridge Inspection Machine employs state-of-the-art technology to meticulously examine cartridges, vials, and syringes, ensuring they meet precise dimensional and quality specifications. With our systems in place, you can be confident in the quality and consistency of your pharmaceutical products.

Customized Solutions: We recognize that the pharmaceutical industry encompasses a wide range of products, from vaccines to injectable drugs. Our inspection solutions can be tailored to suit your specific needs, ensuring that each product type is inspected with precision and accuracy.

Real-time Data Analysis: Our systems provide real-time data analysis, allowing you to monitor the performance of your production processes and make immediate adjustments when necessary. This helps maintain the highest level of quality throughout your manufacturing operations.

Regulatory Compliance: Compliance with regulatory requirements is non-negotiable in the pharmaceutical industry. Our Cartridge Inspection Machine ensures that your products adhere to industry standards and regulatory specifications, helping you avoid costly recalls and regulatory issues.

Why Choose Us?

Industry Expertise: With years of experience in the pharmaceutical sector, we possess the expertise needed to address the unique challenges of drug manufacturing.

Cutting-Edge Technology: We stay at the forefront of technology trends, continuously updating our systems to incorporate the latest advancements in precision measurement.

Cost Efficiency: Our systems are designed to enhance efficiency and reduce waste, ultimately leading to cost savings for your operations.

Customer Support: We offer comprehensive customer support to ensure your inspection systems consistently perform at their best, minimizing downtime and maximizing productivity.

Contact Us:

Ready to elevate the quality of your pharmaceutical manufacturing? Contact us today to discuss your specific requirements and discover how our Cartridge Inspection Machine can enhance your operations. Our team of experts is eager to assist you in finding the ideal solution for your pharmaceutical inspection needs. Count on us for precision, reliability, and innovation in pharmaceutical manufacturing. Your patients deserve nothing less than the best, and we're here to help you deliver it.

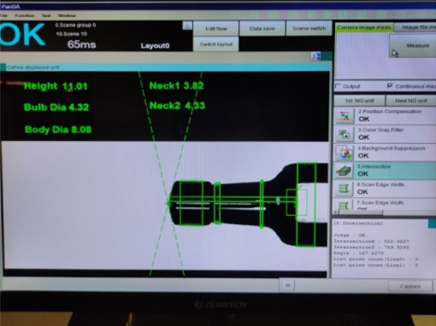

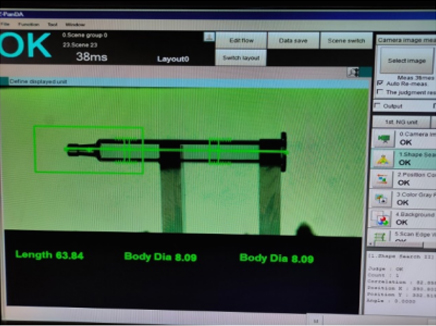

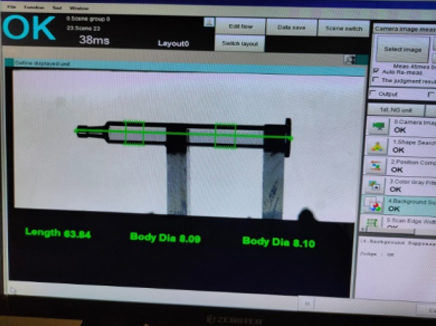

BELOW IMAGES SHOWS THE CAMERA RESULT FOR SAMPLES:

OK SAMPLE

OK SAMPLE

OK SAMPLE

OK SAMPLE

- Camera-1 is mounted on the Line End for identifying the Neck Profile during forming process. The results of OK/NG are given to existing Machine PLC for tracking the defective sample till the Rejection Bin. Tolerance for Accuracy are defined by User.

- Camera-2 is present at the Second Inspection Station, where, the Horizontal Syringe is lifted (>60-70mm) & Rotated to provide multi-image capability in Backlighting. All the Parameters are Inspected for Syringe’s Side Inspection & the Results are given to your existing Machine PLC for OK/NG.

- Camera-3 is present at the Third Inspection Station, where, the Side Camera is used to Capture the Image of Syringe Finger in Backlighting. All the Parameters are Inspected for Syringe’s Side Inspection & the Results are given to your existing Machine PLC for OK/NG.

- All three Camera Results are tracked till the OK/NG Sorting Stations.

- Inspection speed will be up to 50-60 Syringes/Minute (as per your Production Machine Throughput).

- PC based Data-logging System can be optionally provided if required, to store the Statistical Information for the Production line. This will consist of a Desktop PC with a Custom-built Data-Logging Software Package, as per your requirements.