Welcome to Vial Inspection Machine

Elevate Your Vial Inspection with Cutting-Edge Technology

At Vial Inspection Machine, we are dedicated to ushering in a new era of precision and quality assurance in pharmaceutical manufacturing. Our state-of-the-art vial inspection machines are meticulously engineered to meet and exceed the rigorous standards of the pharmaceutical industry, ensuring the safety and reliability of vials and the medications they contain.

Our Mission

Our mission is clear to empower pharmaceutical manufacturers to deliver the highest quality vials to the market, ultimately enhancing patient safety and well-being. We achieve this by providing innovative, technologically advanced vial inspection solutions that set new benchmarks for excellence.

Why Choose Vial Inspection Machine?

1. Unrivaled Expertise: With a wealth of experience in the pharmaceutical machinery sector, our team of experts possesses in-depth knowledge of vial inspection intricacies. This expertise enables us to create machines that not only meet but often surpass industry expectations.

2. State-of-the-Art Technology: Our vial inspection machines are equipped with cutting-edge technology, incorporating advanced imaging systems, artificial intelligence, and precise robotic mechanisms. This technological prowess ensures accurate and efficient inspection, capable of detecting even the most minute defects.

3. Regulatory Compliance and Quality Assurance: We understand the paramount importance of adhering to stringent regulatory standards. Our machines are meticulously designed to meet and exceed FDA, GMP, and other global quality benchmarks, providing pharmaceutical manufacturers with peace of mind and patients with trust in their medications.

4. Tailored Solutions: We recognize that each pharmaceutical company has unique requirements. To accommodate this, we offer customizable options for our inspection machines. Whether you need specific inspection parameters, production rates, or integration with existing manufacturing lines, we can tailor our solutions to meet your needs.

5. Cost-Effective Excellence: Our machines are not just technologically advanced but also cost-effective. We firmly believe that uncompromising quality should be accessible to all pharmaceutical manufacturers. Consequently, we continuously strive to offer competitive pricing without compromising on quality.

Our Product Range

1. Automatic Vial Inspection Machines: These fully automated machines are designed for high-speed vial inspection, ensuring the detection of defects such as particles, cracks, and fill level discrepancies.

2. Semi-Automatic Vial Inspection Machines: Ideal for pharmaceutical companies with varying production volumes, our semi-automatic machines offer precision inspection capabilities with the flexibility of manual loading and unloading.

3. Customized Solutions: Recognizing that your vial inspection needs may be unique, our team is equipped to collaborate with you in designing and fabricating a custom inspection machine tailored precisely to your requirements.

Contact Us

Are you ready to elevate the quality and safety of your vial production? Don't hesitate to reach out to us today to discuss your vial inspection needs. Our team of experts is here to provide guidance, address your inquiries, and help you select the ideal vial inspection machine for your pharmaceutical facility.

Join us in our mission to ensure the highest quality and safety standards for vials worldwide. Vial Inspection Machine - where precision, innovation, and quality converge.

Elevate Your Vial Inspection with Cutting-Edge Technology

At Vial Inspection Machine, we are dedicated to ushering in a new era of precision and quality assurance in pharmaceutical manufacturing. Our state-of-the-art vial inspection machines are meticulously engineered to meet and exceed the rigorous standards of the pharmaceutical industry, ensuring the safety and reliability of vials and the medications they contain.

Our Mission

Our mission is clear to empower pharmaceutical manufacturers to deliver the highest quality vials to the market, ultimately enhancing patient safety and well-being. We achieve this by providing innovative, technologically advanced vial inspection solutions that set new benchmarks for excellence.

Why Choose Vial Inspection Machine?

1. Unrivaled Expertise: With a wealth of experience in the pharmaceutical machinery sector, our team of experts possesses in-depth knowledge of vial inspection intricacies. This expertise enables us to create machines that not only meet but often surpass industry expectations.

2. State-of-the-Art Technology: Our vial inspection machines are equipped with cutting-edge technology, incorporating advanced imaging systems, artificial intelligence, and precise robotic mechanisms. This technological prowess ensures accurate and efficient inspection, capable of detecting even the most minute defects.

3. Regulatory Compliance and Quality Assurance: We understand the paramount importance of adhering to stringent regulatory standards. Our machines are meticulously designed to meet and exceed FDA, GMP, and other global quality benchmarks, providing pharmaceutical manufacturers with peace of mind and patients with trust in their medications.

4. Tailored Solutions: We recognize that each pharmaceutical company has unique requirements. To accommodate this, we offer customizable options for our inspection machines. Whether you need specific inspection parameters, production rates, or integration with existing manufacturing lines, we can tailor our solutions to meet your needs.

5. Cost-Effective Excellence: Our machines are not just technologically advanced but also cost-effective. We firmly believe that uncompromising quality should be accessible to all pharmaceutical manufacturers. Consequently, we continuously strive to offer competitive pricing without compromising on quality.

Our Product Range

1. Automatic Vial Inspection Machines: These fully automated machines are designed for high-speed vial inspection, ensuring the detection of defects such as particles, cracks, and fill level discrepancies.

2. Semi-Automatic Vial Inspection Machines: Ideal for pharmaceutical companies with varying production volumes, our semi-automatic machines offer precision inspection capabilities with the flexibility of manual loading and unloading.

3. Customized Solutions: Recognizing that your vial inspection needs may be unique, our team is equipped to collaborate with you in designing and fabricating a custom inspection machine tailored precisely to your requirements.

Contact Us

Are you ready to elevate the quality and safety of your vial production? Don't hesitate to reach out to us today to discuss your vial inspection needs. Our team of experts is here to provide guidance, address your inquiries, and help you select the ideal vial inspection machine for your pharmaceutical facility.

Join us in our mission to ensure the highest quality and safety standards for vials worldwide. Vial Inspection Machine - where precision, innovation, and quality converge.

The System is designed to Identify following dimensions on vials :

- TOTAL HEIGHT

- SHOULDER HEIGHT

- BASE TO SHOULDER

- NECK HEIGHT

- LIP HEIGHT

- BODY DIA

- NECK DIA

- MOUTH DIA

- BORE DIA

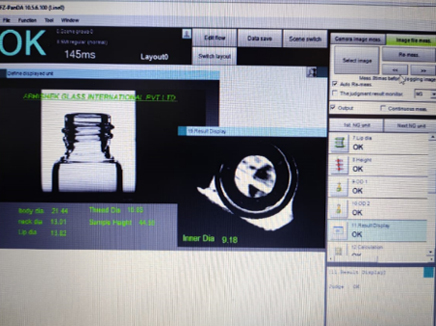

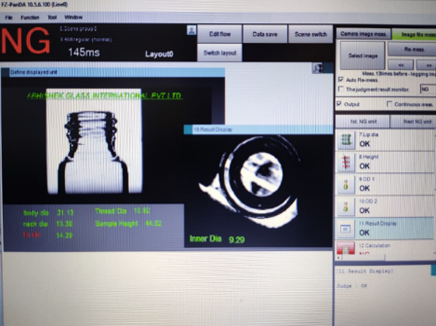

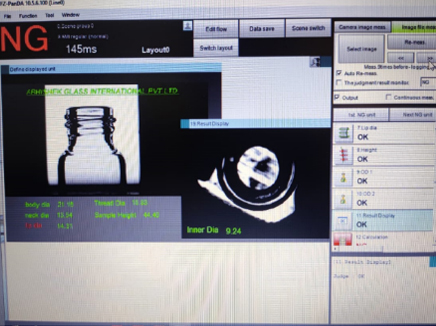

BELOW IMAGES SHOWS THE CAMERA RESULT FOR OK AND BAD SAMPLES :

OK SAMPLE

BAD SAMPLE (LIP DIA)

BAD SAMPLE

BAD SAMPLE (NECK DIA)

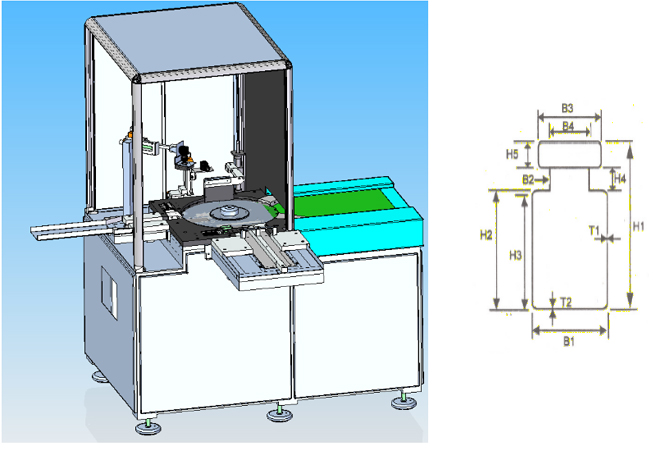

Transfer Conveyor :

- This is the Main Infeed Conveyor through which the Vial samples to be Inspected are continuously fed to the Rotating turret wheel.

Turret Wheel :

- This consists of a disc rotating at high speed that collects the Vial samples from the Main conveyor and carries them through Inspection and rejection Stations. A Double Camera Inspection Station is mounted after the Product enters the disc and there these samples are inspected for the above mentioned various visual parameters.

Rejection Station :

- The defective samples detected by the Camera are segregated out at the Rejection bins and only the Good samples are transferred out to the Good bins.

Other features of the system :

- The system will be designed as per GMP standards.

- Inspection speed will be up to 90-100 Vials/minute.

- Data-logging could be optionally provided if required, to store the Statistical Information for the Production line. This will consist of a Desktop PC with a Custom-built Data-Logging package as per your requirements.