In the dynamic and competitive world of automotive manufacturing, precision is not an option; it's a necessity. Valve guides are crucial components within an engine, and their integrity directly impacts engine performance, emissions, and longevity. This is where our Valve Guide Inspection Systems come into play, ensuring that every valve guide meets the highest standards of quality and reliability in the automotive industry.

Our Mission: At Valve Guide Inspection Systems, our mission is clear: to empower automotive manufacturers with cutting-edge inspection solutions that consistently deliver uncompromising quality. We understand the critical role valve guides play in engine performance, and we are dedicated to helping our clients achieve excellence in their manufacturing processes.

Our Solutions:

Advanced Inspection Technology: Our inspection systems utilize advanced technology to meticulously examine valve guides, ensuring they conform to precise dimensional and quality specifications. With our systems in place, you can be confident in the quality and consistency of your valve guides.

Tailored Solutions: We recognize that the automotive industry is diverse, and different manufacturers have unique requirements. Our inspection solutions can be customized to suit your specific needs, whether you produce valve guides for passenger vehicles, commercial trucks, or high-performance sports cars.

Real-time Data Analysis: Our systems provide real-time data analysis, allowing you to monitor the performance of your production processes and make immediate adjustments when necessary. This ensures that you maintain the highest level of quality throughout your manufacturing operations.

Quality Assurance: With Valve Guide Inspection Systems, you can rest assured that your valve guides adhere to industry standards and regulatory requirements. This commitment to quality safeguards your reputation and reduces costly recalls.

Why Choose Us?

Industry Expertise: With years of experience in dimensional inspection, we possess the expertise needed to address the unique challenges of the automotive industry.

Cutting-Edge Technology: We stay at the forefront of technology trends, continuously updating our systems to incorporate the latest advancements in precision measurement.

Cost Efficiency: Our systems are designed to enhance efficiency and reduce waste, ultimately leading to cost savings for your operations.

Customer Support: We offer comprehensive customer support to ensure your inspection systems consistently perform at their best, minimizing downtime.

Contact Us

Ready to elevate the quality of your automotive manufacturing? Contact us today to discuss your specific requirements and discover how our Valve Guide Inspection Systems can enhance your operations. Our team of experts is eager to assist you in finding the ideal solution for your valve guide inspection needs. Count on us for precision, reliability, and innovation in automotive manufacturing.

Our Mission: At Valve Guide Inspection Systems, our mission is clear: to empower automotive manufacturers with cutting-edge inspection solutions that consistently deliver uncompromising quality. We understand the critical role valve guides play in engine performance, and we are dedicated to helping our clients achieve excellence in their manufacturing processes.

Our Solutions:

Advanced Inspection Technology: Our inspection systems utilize advanced technology to meticulously examine valve guides, ensuring they conform to precise dimensional and quality specifications. With our systems in place, you can be confident in the quality and consistency of your valve guides.

Tailored Solutions: We recognize that the automotive industry is diverse, and different manufacturers have unique requirements. Our inspection solutions can be customized to suit your specific needs, whether you produce valve guides for passenger vehicles, commercial trucks, or high-performance sports cars.

Real-time Data Analysis: Our systems provide real-time data analysis, allowing you to monitor the performance of your production processes and make immediate adjustments when necessary. This ensures that you maintain the highest level of quality throughout your manufacturing operations.

Quality Assurance: With Valve Guide Inspection Systems, you can rest assured that your valve guides adhere to industry standards and regulatory requirements. This commitment to quality safeguards your reputation and reduces costly recalls.

Why Choose Us?

Industry Expertise: With years of experience in dimensional inspection, we possess the expertise needed to address the unique challenges of the automotive industry.

Cutting-Edge Technology: We stay at the forefront of technology trends, continuously updating our systems to incorporate the latest advancements in precision measurement.

Cost Efficiency: Our systems are designed to enhance efficiency and reduce waste, ultimately leading to cost savings for your operations.

Customer Support: We offer comprehensive customer support to ensure your inspection systems consistently perform at their best, minimizing downtime.

Contact Us

Ready to elevate the quality of your automotive manufacturing? Contact us today to discuss your specific requirements and discover how our Valve Guide Inspection Systems can enhance your operations. Our team of experts is eager to assist you in finding the ideal solution for your valve guide inspection needs. Count on us for precision, reliability, and innovation in automotive manufacturing.

DEFECTIVE / OKAY SAMPLE LIST :

- Detection of the surface defects for the casting components on all the side, i.e. Both the sides and the complete cylindrical surface of the component.

- Detection of the mixed-up component (Another variant) in a given running batch.

MACHINE DETAILS :

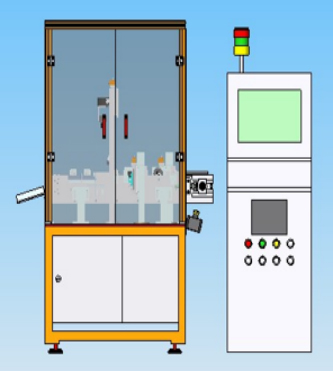

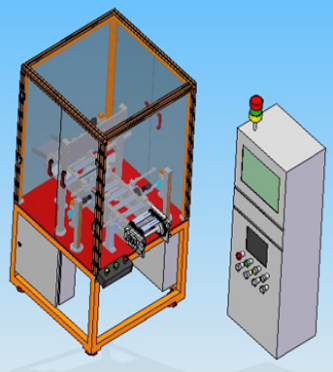

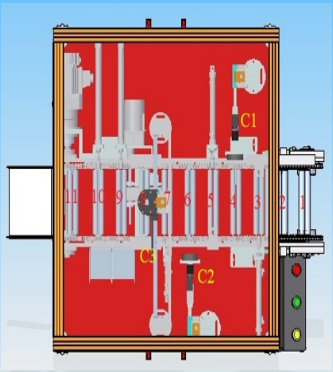

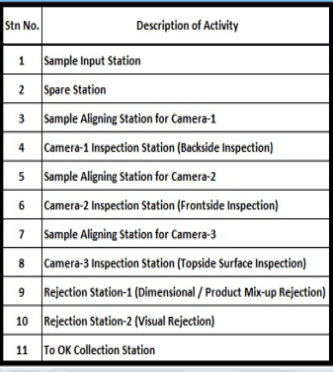

- Basically, this is a standalone off-line machine where Cylindrical casting components will be inspected for the various surface defects and the mixing of the products than the running batch component.

- Operator will have to place components at specific location on the indexing roller conveyor. Then components will be taken to three different Camera based Inspection station where component will be inspected for the required parameters from all the sides viz. Left side, Right side and the

- Total cylindrical surface of the component. These inspection stations will have suitable cameras, Lenses and the Lighting system.

- Based upon the Result, Component will be sent to either at the trays having Good Quality products OR at the Rejection tray. There shall be two separate rejection trays collecting components having Surface defects and Mixed-up components respectively.

- This machine can run at the Max. speed of 15 Components/minute.