Introduction:

In the fast-paced world of automotive manufacturing, precision and reliability are paramount. As vehicle designs evolve, so do the demands on critical components like axles. To meet these demands, the automotive industry relies on cutting-edge technology to ensure the highest standards in axle quality. Introducing our Dynamic Axle Dimensional Inspection Systems, designed specifically to address the rigorous needs of the automotive sector.

Key Features:

Real-time Precision: Our Dynamic Axle Dimensional Inspection Systems are engineered for precision and speed. They provide real-time measurements of critical axle dimensions, guaranteeing accuracy to the micrometer.

Advanced Optical Sensors: We employ state-of-the-art optical sensors and laser scanning technology to capture detailed axle profiles. This ensures every contour, feature, and dimension is thoroughly inspected.

Customizable Inspection Parameters: Tailor inspections to your specific axle designs. Our systems can be programmed to detect variations in length, diameter, roundness, concentricity, and more.

High-speed Processing: With rapid data acquisition and analysis capabilities, our systems keep pace with modern production lines, ensuring that inspection doesn't become a bottleneck.

Data Logging and Analysis: Comprehensive data logging and analysis tools allow for easy tracking of axle quality over time, facilitating process optimization and quality control.

Automatic Sorting: The systems automatically sort axles into categories based on their dimensional conformity, streamlining the manufacturing process and minimizing human error.

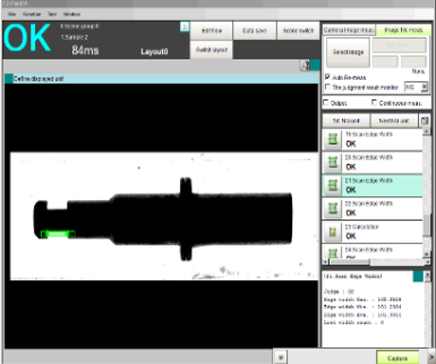

User-friendly Interface: Operating our Dynamic Axle Dimensional Inspection Systems is straightforward, thanks to an intuitive user interface. Monitor inspections in real-time and access historical data with ease.

Benefits:

Enhanced Product Quality: Ensure that every axle meets or exceeds industry standards, reducing the risk of product recalls and warranty claims.

Increased Productivity: Rapid, accurate inspections keep production lines running smoothly, leading to cost savings and improved efficiency.

Cost Reduction: By identifying and rejecting non-conforming axles early in the production process, material waste is minimized, and resources are conserved.

Streamlined Operations: Automatic sorting of axles minimizes the need for manual intervention, reducing labor costs and increasing throughput.

Data-Driven Decision Making: Analyze inspection data to fine-tune manufacturing processes and drive continuous improvement efforts.

Applications:

Our Dynamic Axle Dimensional Inspection Systems are indispensable in the automotive industry and can be applied to various types of axles, including:

Front and rear axles

Drive and non-drive axles

Solid and independent suspension axles

Commercial vehicle axles

Conclusion:

Invest in the future of axle quality control with our Dynamic Axle Dimensional Inspection Systems. At Sigma vision And Robotics, we are committed to delivering cutting-edge technology that empowers the automotive industry to meet ever-increasing quality demands. Contact us today to learn more about how our systems can revolutionize your manufacturing processes.

In the fast-paced world of automotive manufacturing, precision and reliability are paramount. As vehicle designs evolve, so do the demands on critical components like axles. To meet these demands, the automotive industry relies on cutting-edge technology to ensure the highest standards in axle quality. Introducing our Dynamic Axle Dimensional Inspection Systems, designed specifically to address the rigorous needs of the automotive sector.

Key Features:

Real-time Precision: Our Dynamic Axle Dimensional Inspection Systems are engineered for precision and speed. They provide real-time measurements of critical axle dimensions, guaranteeing accuracy to the micrometer.

Advanced Optical Sensors: We employ state-of-the-art optical sensors and laser scanning technology to capture detailed axle profiles. This ensures every contour, feature, and dimension is thoroughly inspected.

Customizable Inspection Parameters: Tailor inspections to your specific axle designs. Our systems can be programmed to detect variations in length, diameter, roundness, concentricity, and more.

High-speed Processing: With rapid data acquisition and analysis capabilities, our systems keep pace with modern production lines, ensuring that inspection doesn't become a bottleneck.

Data Logging and Analysis: Comprehensive data logging and analysis tools allow for easy tracking of axle quality over time, facilitating process optimization and quality control.

Automatic Sorting: The systems automatically sort axles into categories based on their dimensional conformity, streamlining the manufacturing process and minimizing human error.

User-friendly Interface: Operating our Dynamic Axle Dimensional Inspection Systems is straightforward, thanks to an intuitive user interface. Monitor inspections in real-time and access historical data with ease.

Benefits:

Enhanced Product Quality: Ensure that every axle meets or exceeds industry standards, reducing the risk of product recalls and warranty claims.

Increased Productivity: Rapid, accurate inspections keep production lines running smoothly, leading to cost savings and improved efficiency.

Cost Reduction: By identifying and rejecting non-conforming axles early in the production process, material waste is minimized, and resources are conserved.

Streamlined Operations: Automatic sorting of axles minimizes the need for manual intervention, reducing labor costs and increasing throughput.

Data-Driven Decision Making: Analyze inspection data to fine-tune manufacturing processes and drive continuous improvement efforts.

Applications:

Our Dynamic Axle Dimensional Inspection Systems are indispensable in the automotive industry and can be applied to various types of axles, including:

Front and rear axles

Drive and non-drive axles

Solid and independent suspension axles

Commercial vehicle axles

Conclusion:

Invest in the future of axle quality control with our Dynamic Axle Dimensional Inspection Systems. At Sigma vision And Robotics, we are committed to delivering cutting-edge technology that empowers the automotive industry to meet ever-increasing quality demands. Contact us today to learn more about how our systems can revolutionize your manufacturing processes.

DYNAMIC AXLE DIMENSIONAL INSPECTION

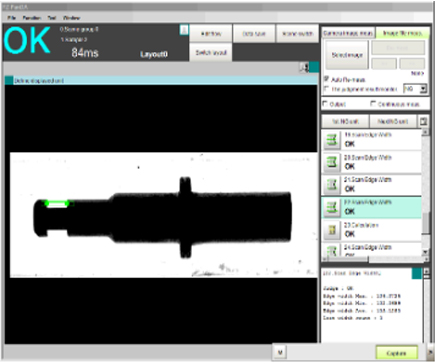

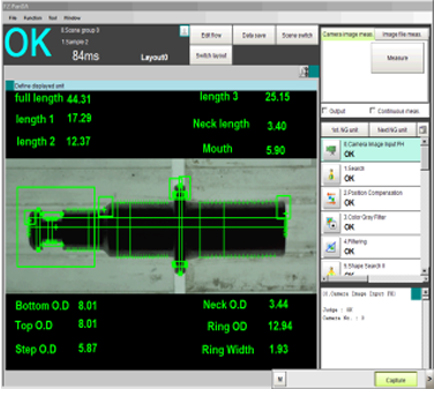

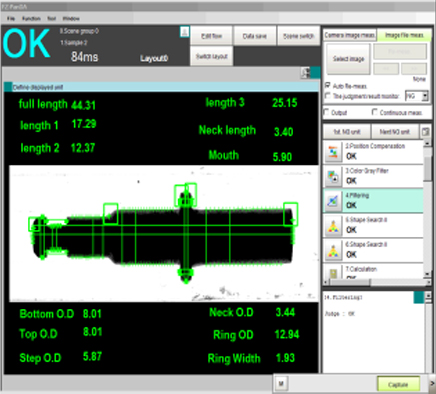

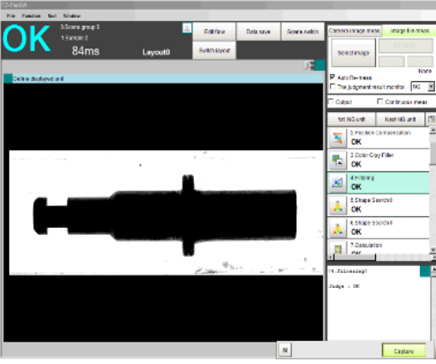

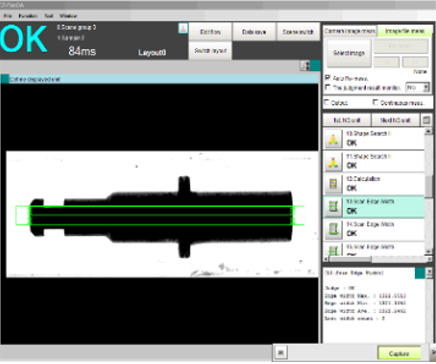

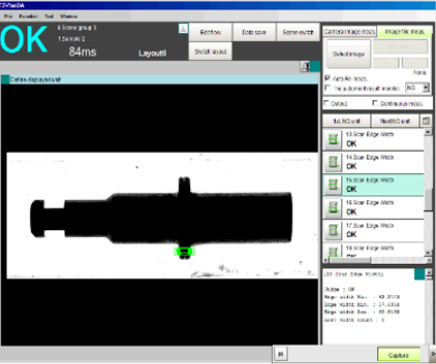

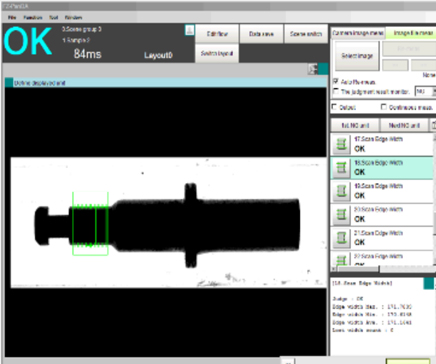

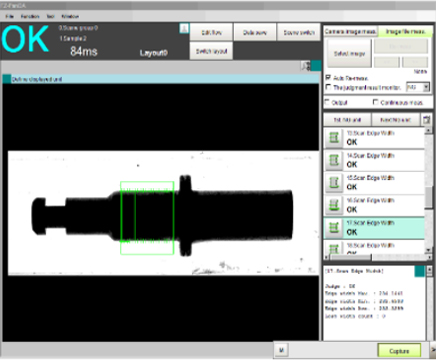

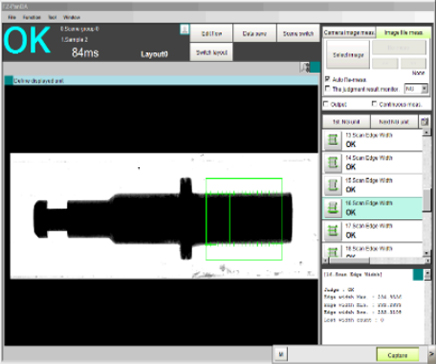

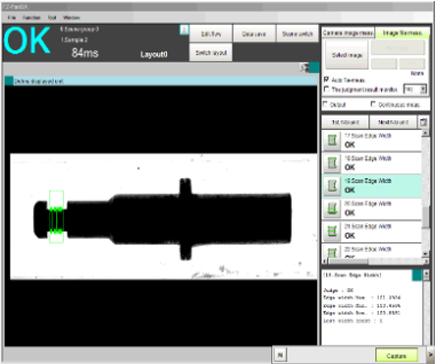

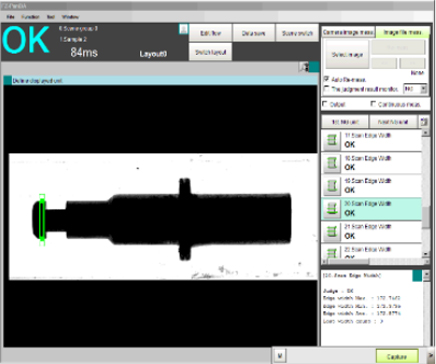

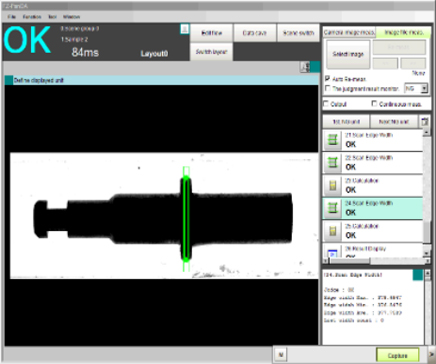

BELOW IMAGES SHOWS THE CAMERA RESULT FOR SAMPLES :

FILTERED IMAGE

FULL LENGTH MEASUREMENT

RING WIDTH MEASUREMENT

STEP OD MEASUREMENT

TOP OD MEASUREMENT

BOTTOM OD MEASUREMENT

NECK OD EASUREMENT

MOUTH OD MEASUREMENT

RING OD MEASUREMENT

NECK LENGTH MEASUREMENT