Welcome to the Flange Counting & Manual Inspection System

Introducing the Flange Counting & Manual Inspection System, a cutting-edge solution designed to streamline and enhance the precision of your manufacturing process. Our system offers an efficient way to count and inspect flanges while ensuring the highest quality standards in your production line.

Key Features

• Accurate Flange Counting: Our system uses advanced technology to accurately count flanges, reducing the margin for error in your manufacturing process.

• Manual Inspection: With our system, you can easily inspect each flange for quality, ensuring that only top-quality products make it to the market.

• Real-time Data: Stay informed about your production progress with real-time data and reports generated by the system.

• User-Friendly Interface: Our intuitive interface makes it easy for operators to use the system with minimal training.

• Customizable Solutions: We understand that every manufacturing process is unique. That's why we offer customizable solutions to fit your specific requirements.

Benefits

• Enhanced Productivity: Our Flange Counting & Manual Inspection System helps you achieve higher production rates with reduced errors.

• Improved Quality Control: Ensure that only products meeting your quality standards are shipped to customers.

• Reduced Labor Costs: Automate the counting and inspection process, reducing the need for manual labor.

• Real-time Monitoring: Keep track of your manufacturing process in real time and make informed decisions.

Why Choose Our System?

• Proven Reliability: Our system has been tried and tested in various industries, delivering consistent results.

• Tailored Solutions: We work closely with our clients to provide custom solutions that meet their unique needs.

• Dedicated Support: Our team is committed to offering exceptional customer support, ensuring your system runs smoothly.

• Cutting-Edge Technology: We stay at the forefront of technology to deliver the best solutions to our clients.

Industries We Serve

Our Flange Counting & Manual Inspection System is versatile and can benefit various industries, including:

• Manufacturing

• Automotive

• Aerospace

• Steel Production

• Construction

Contact Us

If you're interested in learning more about our Flange Counting & Manual Inspection System or would like to discuss how it can benefit your business, please get in touch with us. We're here to provide the solutions you need. Explore our website to discover more about the Flange Counting & Manual Inspection System and how it can optimize your manufacturing process. We look forward to helping your business achieve greater efficiency and quality control.

Introducing the Flange Counting & Manual Inspection System, a cutting-edge solution designed to streamline and enhance the precision of your manufacturing process. Our system offers an efficient way to count and inspect flanges while ensuring the highest quality standards in your production line.

Key Features

• Accurate Flange Counting: Our system uses advanced technology to accurately count flanges, reducing the margin for error in your manufacturing process.

• Manual Inspection: With our system, you can easily inspect each flange for quality, ensuring that only top-quality products make it to the market.

• Real-time Data: Stay informed about your production progress with real-time data and reports generated by the system.

• User-Friendly Interface: Our intuitive interface makes it easy for operators to use the system with minimal training.

• Customizable Solutions: We understand that every manufacturing process is unique. That's why we offer customizable solutions to fit your specific requirements.

Benefits

• Enhanced Productivity: Our Flange Counting & Manual Inspection System helps you achieve higher production rates with reduced errors.

• Improved Quality Control: Ensure that only products meeting your quality standards are shipped to customers.

• Reduced Labor Costs: Automate the counting and inspection process, reducing the need for manual labor.

• Real-time Monitoring: Keep track of your manufacturing process in real time and make informed decisions.

Why Choose Our System?

• Proven Reliability: Our system has been tried and tested in various industries, delivering consistent results.

• Tailored Solutions: We work closely with our clients to provide custom solutions that meet their unique needs.

• Dedicated Support: Our team is committed to offering exceptional customer support, ensuring your system runs smoothly.

• Cutting-Edge Technology: We stay at the forefront of technology to deliver the best solutions to our clients.

Industries We Serve

Our Flange Counting & Manual Inspection System is versatile and can benefit various industries, including:

• Manufacturing

• Automotive

• Aerospace

• Steel Production

• Construction

Contact Us

If you're interested in learning more about our Flange Counting & Manual Inspection System or would like to discuss how it can benefit your business, please get in touch with us. We're here to provide the solutions you need. Explore our website to discover more about the Flange Counting & Manual Inspection System and how it can optimize your manufacturing process. We look forward to helping your business achieve greater efficiency and quality control.

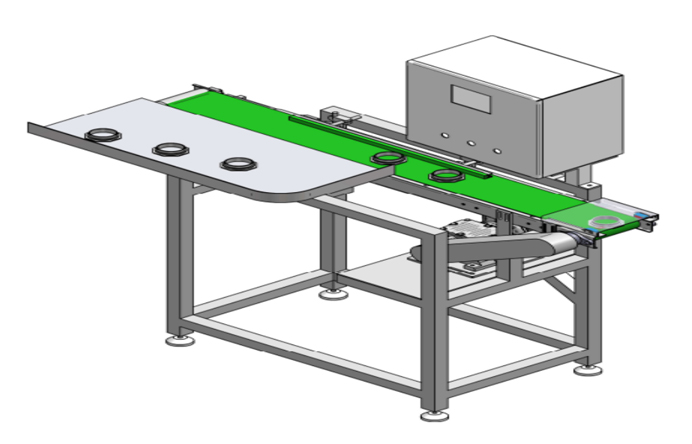

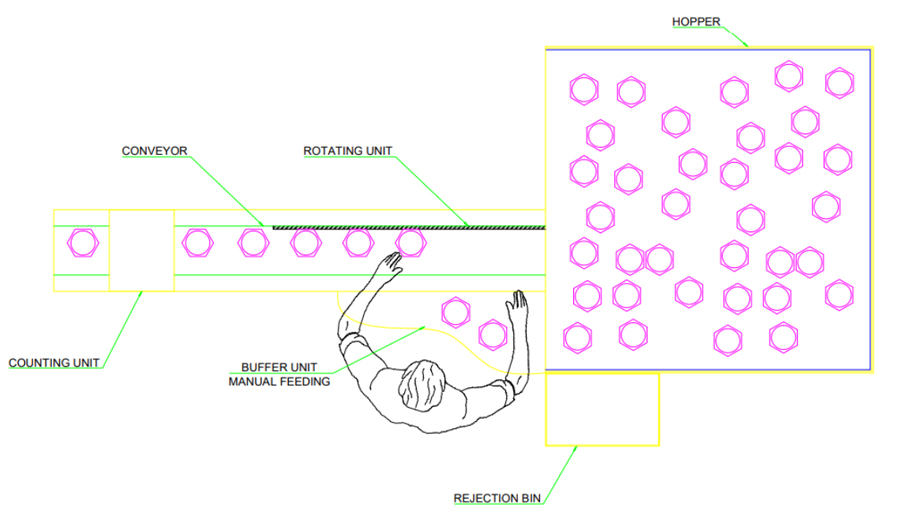

SYSTEM OVERVIEW :

- The Proposed Flange Counting System consist of a Product Hopper & a Counting Conveyor with Manual Inspection in 360degree.

- Product Hopper includes a 1mtr (L) X 1mtr (W) X 800mm (H) MS Box enclosed from 3 sides completely & an Exit from 4th side. It has an Holding Capacity of almost 1500-2000 Flange samples at a time. At the Exit, there will be a dead plate on which the samples will be pulled out. On the right-hand side of the Operator will be present Rejection Bin for holding manually sorted out defective samples.

- Counting Conveyor consists of a 1500mm Length X 150mm Width Motorized Conveyor. A Variable Frequency Drive (VFD) will be provided for controlling the Linear Speed of the Conveyor. A Product Sensor will be present to count the Total number of samples getting filled in Collection Bin. A Counter will be present to Show the real-time count of these collected samples inside the Bin.