Introduction:

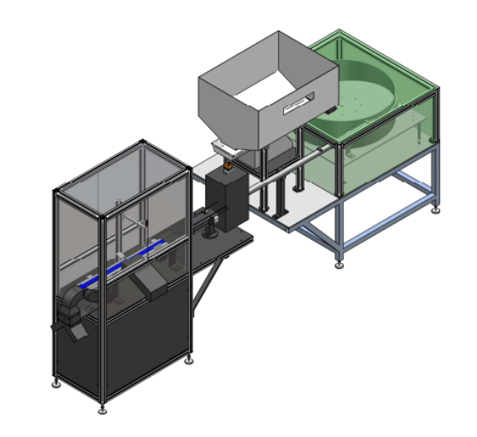

Welcome to the future of precision and efficiency in drip irrigation technology! Our Flat Dripper Inspection Machine 1000 @ minute is designed to revolutionize the quality control process for flat drippers in the agriculture industry. At Sigma Vision and Robotics, we are committed to delivering innovative solutions that empower farmers to achieve higher yields with greater ease. Let's delve into the features and benefits of the FDIM-1000, your trusted partner in drip irrigation quality assurance.

Key Features:

High-Speed Inspection: The FDIM-1000 boasts a high-speed inspection system capable of examining up to 950-1000 flat drippers per minute. This remarkable speed ensures efficient quality control while maintaining product integrity.

Precision Vision System: Equipped with state-of-the-art vision technology, our machine detects even the minutest defects, such as short molding samples, Flash defect samples, Cut/damaged samples, Filter-hole blocked samples, foreign mix-up sample (Variants with major color difference) guaranteeing that only top-quality flat drippers make it to the field.

Customizable Inspection Parameters: Tailor the inspection criteria to your specific needs. The FDIM-1000 allows you to set parameters for various flat dripper attributes, ensuring flexibility and adaptability for different production requirements.

User-Friendly Interface: Our user-friendly interface simplifies operation, making it accessible for all skill levels. The intuitive design minimizes the learning curve, reducing downtime and increasing productivity. The FDIM-1000 collects comprehensive data during the inspection process. This data can be easily exported for analysis, allowing you to fine-tune your production processes and maintain quality standards consistently.

Benefits:

Data Analysis and Reporting: Enhanced Product Quality: With its unparalleled precision, the FDIM-1000 ensures that only flawless flat drippers reach your customers. This quality assurance boosts your brand's reputation and customer satisfaction.

Increased Efficiency: Say goodbye to time-consuming manual inspections. The FDIM-1000 automates the process, freeing up your workforce for more valuable tasks and reducing labor costs.

Cost Savings: Minimize the risk of defective products reaching the market, saving you money on potential recalls or replacements.

Sustainable Agriculture: Drip irrigation is known for its water-saving benefits. By ensuring that your flat drippers function optimally, you contribute to sustainable and responsible water use in agriculture.

Competitive Edge: Stay ahead of the competition by delivering consistently high-quality products that meet the stringent demands of modern agriculture.

Applications:

The FDIM-1000 is suitable for a wide range of flat dripper types and sizes, making it a versatile solution for various agricultural applications. It can be seamlessly integrated into your production line, whether you manufacture flat drippers for large-scale farming or specialized niche markets.

Conclusion:

Invest in the future of drip irrigation quality control with the FDIM-1000 from Sigma Vision and Robotics. Elevate your product quality, reduce costs, and enhance your reputation in the agriculture industry. Join us in shaping the future of sustainable and efficient agriculture, one drip at a time.

Contact us today to learn more about how the FDIM-1000 can transform your flat dripper quality control process. Together, we can revolutionize the way you irrigate and cultivate.

Welcome to the future of precision and efficiency in drip irrigation technology! Our Flat Dripper Inspection Machine 1000 @ minute is designed to revolutionize the quality control process for flat drippers in the agriculture industry. At Sigma Vision and Robotics, we are committed to delivering innovative solutions that empower farmers to achieve higher yields with greater ease. Let's delve into the features and benefits of the FDIM-1000, your trusted partner in drip irrigation quality assurance.

Key Features:

High-Speed Inspection: The FDIM-1000 boasts a high-speed inspection system capable of examining up to 950-1000 flat drippers per minute. This remarkable speed ensures efficient quality control while maintaining product integrity.

Precision Vision System: Equipped with state-of-the-art vision technology, our machine detects even the minutest defects, such as short molding samples, Flash defect samples, Cut/damaged samples, Filter-hole blocked samples, foreign mix-up sample (Variants with major color difference) guaranteeing that only top-quality flat drippers make it to the field.

Customizable Inspection Parameters: Tailor the inspection criteria to your specific needs. The FDIM-1000 allows you to set parameters for various flat dripper attributes, ensuring flexibility and adaptability for different production requirements.

User-Friendly Interface: Our user-friendly interface simplifies operation, making it accessible for all skill levels. The intuitive design minimizes the learning curve, reducing downtime and increasing productivity. The FDIM-1000 collects comprehensive data during the inspection process. This data can be easily exported for analysis, allowing you to fine-tune your production processes and maintain quality standards consistently.

Benefits:

Data Analysis and Reporting: Enhanced Product Quality: With its unparalleled precision, the FDIM-1000 ensures that only flawless flat drippers reach your customers. This quality assurance boosts your brand's reputation and customer satisfaction.

Increased Efficiency: Say goodbye to time-consuming manual inspections. The FDIM-1000 automates the process, freeing up your workforce for more valuable tasks and reducing labor costs.

Cost Savings: Minimize the risk of defective products reaching the market, saving you money on potential recalls or replacements.

Sustainable Agriculture: Drip irrigation is known for its water-saving benefits. By ensuring that your flat drippers function optimally, you contribute to sustainable and responsible water use in agriculture.

Competitive Edge: Stay ahead of the competition by delivering consistently high-quality products that meet the stringent demands of modern agriculture.

Applications:

The FDIM-1000 is suitable for a wide range of flat dripper types and sizes, making it a versatile solution for various agricultural applications. It can be seamlessly integrated into your production line, whether you manufacture flat drippers for large-scale farming or specialized niche markets.

Conclusion:

Invest in the future of drip irrigation quality control with the FDIM-1000 from Sigma Vision and Robotics. Elevate your product quality, reduce costs, and enhance your reputation in the agriculture industry. Join us in shaping the future of sustainable and efficient agriculture, one drip at a time.

Contact us today to learn more about how the FDIM-1000 can transform your flat dripper quality control process. Together, we can revolutionize the way you irrigate and cultivate.

The System is designed to Identify following defects on Flat drippers :

- Short Molding samples

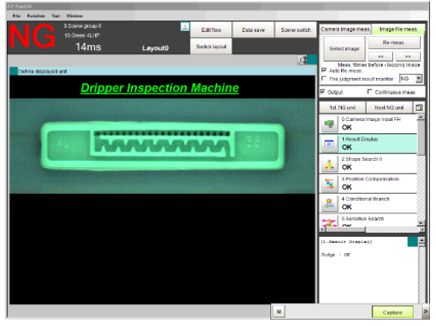

- Flash defect samples

- Cut /Damaged samples

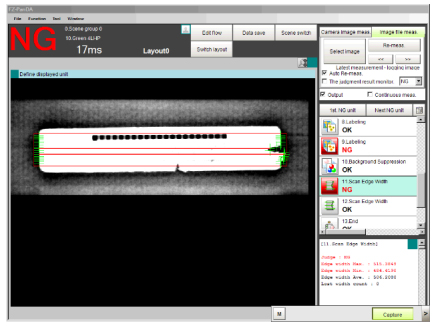

- Filter-holes blocked samples

- Foreign mix-up sample (Variants with major Color difference)

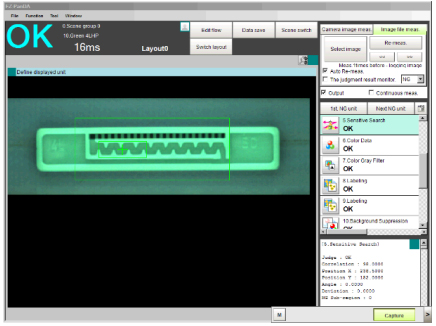

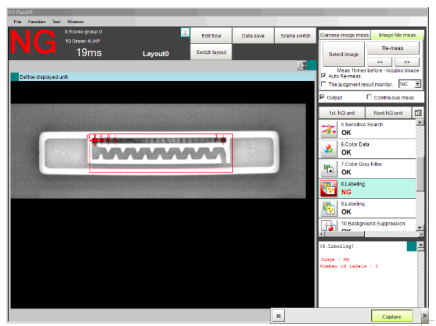

BELOW IMAGES SHOWS THE CAMERA RESULT FOR OK AND BAD SAMPLES :

OK SAMPLE

BAD SAMPLE (FLASH DEFECT)

BAD SAMPLE (SHORT MOULD)

BAD SAMPLE (FILTER HOLES BLOCKED)

Product Hopper :

- The products to be inspected are manually loaded to the Hopper.

Feeding Chute :

- This system is designed to collect the flat drippers in uniform fashion & send it to Inspection Station for Inspection purpose.

Camera based Inspection System :

- The Camera based Inspection Station consists of Single High-Resolution Color Camera System with a Very Higher End Digital Processor for identifying the OK/NG samples as per your requirements.

- Std Machine is capable of inspecting 950 to 1000 components per minute depending on the Quality & flow of the dripper samples.

High Speed Rejection System :

- This consists of High-Speed Pneumatic operated nozzle to sort out the defective dripper samples from the Production line.

- Faulty drippers will be collected in Rejection Bin & OK samples will be passed on to Good samples collection bin respectively.

Output Batch Diverter System :

- This consists of Pneumatic operated diverter assembly which diverts Good materials from One Collection bin to Another Collection bin. (Collection Bin is in Customer’s Scope of Supply).

- This is done on the basis of the Product quantity set per Batch.