Introduction:

Welcome to the future of precision agriculture! Our Flat Dripper Inspection Machine 600 @ minute is designed to revolutionize the quality control process for flat drippers used in drip irrigation systems. With meticulous attention to detail and advanced technology, the FDIM-600 ensures that every flat dripper meets the highest standards of performance and durability. This state-of-the-art machine is a game-changer for manufacturers and growers alike.

Key Features:

High-Speed Inspection: The FDIM-600 is capable of inspecting flat drippers at an impressive speed, significantly increasing production efficiency without compromising on accuracy. It can handle a large volume of production 24 hours day and night, making it ideal for high-throughput manufacturing environments.

Precision Imaging: Equipped with advanced imaging technology, our inspection machine captures every detail of the flat dripper's structure, detecting even the tiniest defects and irregularities. This ensures that only flawless drippers move forward in the production line.

Multi-Point Inspection: The FDIM-600 conducts a comprehensive multi-point inspection, including defects like short molding samples, Flash defect samples, Cut/damaged samples, Filter-hole blocked samples, foreign mix-up sample (Variants with major color difference) with precision. It guarantees that the drippers meet stringent quality standards.

User-Friendly Interface: We understand the importance of user-friendliness in manufacturing environments. Thes FDIM-600 features an intuitive interface that allows operators to set parameters, monitor the inspection process, and receive real-time feedback with ease.

Customizable Settings: Tailor the inspection process to your specific requirements. The machine offers customizable settings, allowing you to adjust inspection criteria to match your product specifications precisely.

Data Logging: Keep a detailed record of the inspection results for each dripper. This data can be invaluable for quality control, product traceability, and process optimization.

Integration Capabilities: Seamlessly integrate the FDIM- 600 into your existing production line. It can communicate with other machinery and systems, ensuring a smooth and synchronized workflow.

Benefits:

Enhanced Product Quality: With the FDIM-600, you can be confident that every flat dripper leaving your production line meets the highest quality standards, reducing the risk of product recalls and customer dissatisfaction.

Increased Productivity: Improve production efficiency by automating the inspection process. The high-speed capabilities of the machine mean faster throughput and reduced labor costs

Cost Savings: Minimize waste by catching defects early in the production process. This results in significant cost savings by reducing the number of substandard drippers produced.

Peace of Mind: Rest easy knowing that your drip irrigation components are of the utmost quality, ensuring optimal performance and longevity for your customers

Applications:

The FDIM-600 is an invaluable addition to any manufacturer involved in the production of flat drippers for drip irrigation systems. Its precision and speed make it suitable for a wide range of applications, including:ss

• Agriculture

• Horticulture

• Greenhouse farming

• Landscaping

• Residential and commercial irrigation systems

Conclusion:

Invest in the future of drip irrigation quality control with the Flat Dripper Inspection Machine FDIM-600. Elevate your product quality, streamline your production processes, and stay ahead of the competition. Contact us today to learn more about how the FDIM-600 can transform your manufacturing operations and help you deliver superior flat drippers to your customers.

Welcome to the future of precision agriculture! Our Flat Dripper Inspection Machine 600 @ minute is designed to revolutionize the quality control process for flat drippers used in drip irrigation systems. With meticulous attention to detail and advanced technology, the FDIM-600 ensures that every flat dripper meets the highest standards of performance and durability. This state-of-the-art machine is a game-changer for manufacturers and growers alike.

Key Features:

High-Speed Inspection: The FDIM-600 is capable of inspecting flat drippers at an impressive speed, significantly increasing production efficiency without compromising on accuracy. It can handle a large volume of production 24 hours day and night, making it ideal for high-throughput manufacturing environments.

Precision Imaging: Equipped with advanced imaging technology, our inspection machine captures every detail of the flat dripper's structure, detecting even the tiniest defects and irregularities. This ensures that only flawless drippers move forward in the production line.

Multi-Point Inspection: The FDIM-600 conducts a comprehensive multi-point inspection, including defects like short molding samples, Flash defect samples, Cut/damaged samples, Filter-hole blocked samples, foreign mix-up sample (Variants with major color difference) with precision. It guarantees that the drippers meet stringent quality standards.

User-Friendly Interface: We understand the importance of user-friendliness in manufacturing environments. Thes FDIM-600 features an intuitive interface that allows operators to set parameters, monitor the inspection process, and receive real-time feedback with ease.

Customizable Settings: Tailor the inspection process to your specific requirements. The machine offers customizable settings, allowing you to adjust inspection criteria to match your product specifications precisely.

Data Logging: Keep a detailed record of the inspection results for each dripper. This data can be invaluable for quality control, product traceability, and process optimization.

Integration Capabilities: Seamlessly integrate the FDIM- 600 into your existing production line. It can communicate with other machinery and systems, ensuring a smooth and synchronized workflow.

Benefits:

Enhanced Product Quality: With the FDIM-600, you can be confident that every flat dripper leaving your production line meets the highest quality standards, reducing the risk of product recalls and customer dissatisfaction.

Increased Productivity: Improve production efficiency by automating the inspection process. The high-speed capabilities of the machine mean faster throughput and reduced labor costs

Cost Savings: Minimize waste by catching defects early in the production process. This results in significant cost savings by reducing the number of substandard drippers produced.

Peace of Mind: Rest easy knowing that your drip irrigation components are of the utmost quality, ensuring optimal performance and longevity for your customers

Applications:

The FDIM-600 is an invaluable addition to any manufacturer involved in the production of flat drippers for drip irrigation systems. Its precision and speed make it suitable for a wide range of applications, including:ss

• Agriculture

• Horticulture

• Greenhouse farming

• Landscaping

• Residential and commercial irrigation systems

Conclusion:

Invest in the future of drip irrigation quality control with the Flat Dripper Inspection Machine FDIM-600. Elevate your product quality, streamline your production processes, and stay ahead of the competition. Contact us today to learn more about how the FDIM-600 can transform your manufacturing operations and help you deliver superior flat drippers to your customers.

The System is designed to Identify following defects on Flat drippers :

- Short Molding samples

- Flash defect samples

- Cut /Damaged samples

- Filter-holes blocked samples

- Foreign mix-up sample (Variants with major Color difference)

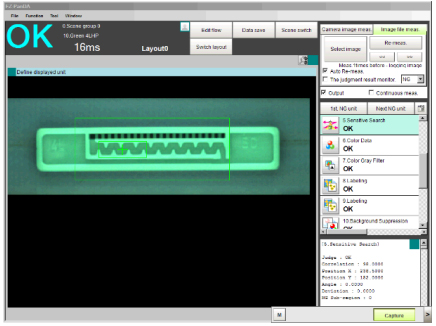

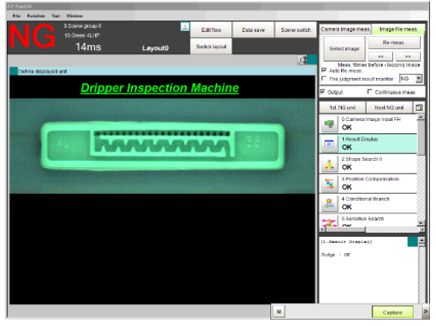

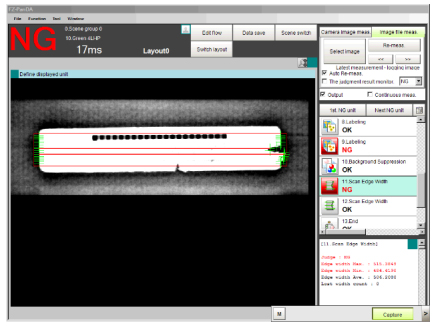

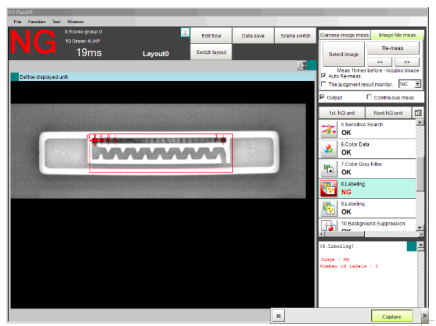

BELOW IMAGES SHOWS THE CAMERA RESULT FOR OK AND BAD SAMPLES :

OK SAMPLE

BAD SAMPLE (FLASH DEFECT)

BAD SAMPLE (SHORT MOULD)

BAD SAMPLE (FILTER HOLES BLOCKED)

Product Hopper :

- The products to be inspected are manually loaded to the Hopper.

Feeding Chute :

- This system is designed to collect the flat drippers in uniform fashion & send it to Inspection Station for Inspection purpose.

Camera based Inspection System :

- The Camera based Inspection Station consists of Single High-Resolution Color Camera System with a Very Higher End Digital Processor for identifying the OK/NG samples as per your requirements.

- Std Machine is capable of inspecting 600 to 650 components per minute depending on the Quality & flow of the dripper samples.

High Speed Rejection System :

- This consists of High-Speed Pneumatic operated nozzle to sort out the defective dripper samples from the Production line.

- Faulty drippers will be collected in Rejection Bin & OK samples will be passed on to Good samples collection bin respectively.

Output Batch Diverter System :

- This consists of Pneumatic operated diverter assembly which diverts Good materials from One Collection bin to Another Collection bin. (Collection Bin is in Customer’s Scope of Supply).

- This is done on the basis of the Product quantity set per Batch.